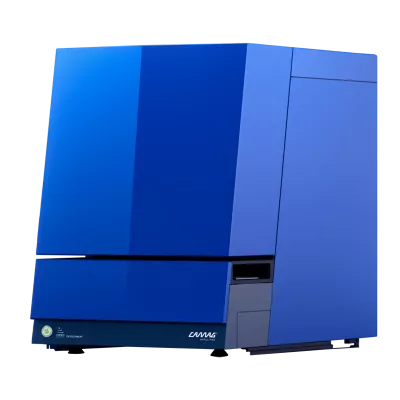

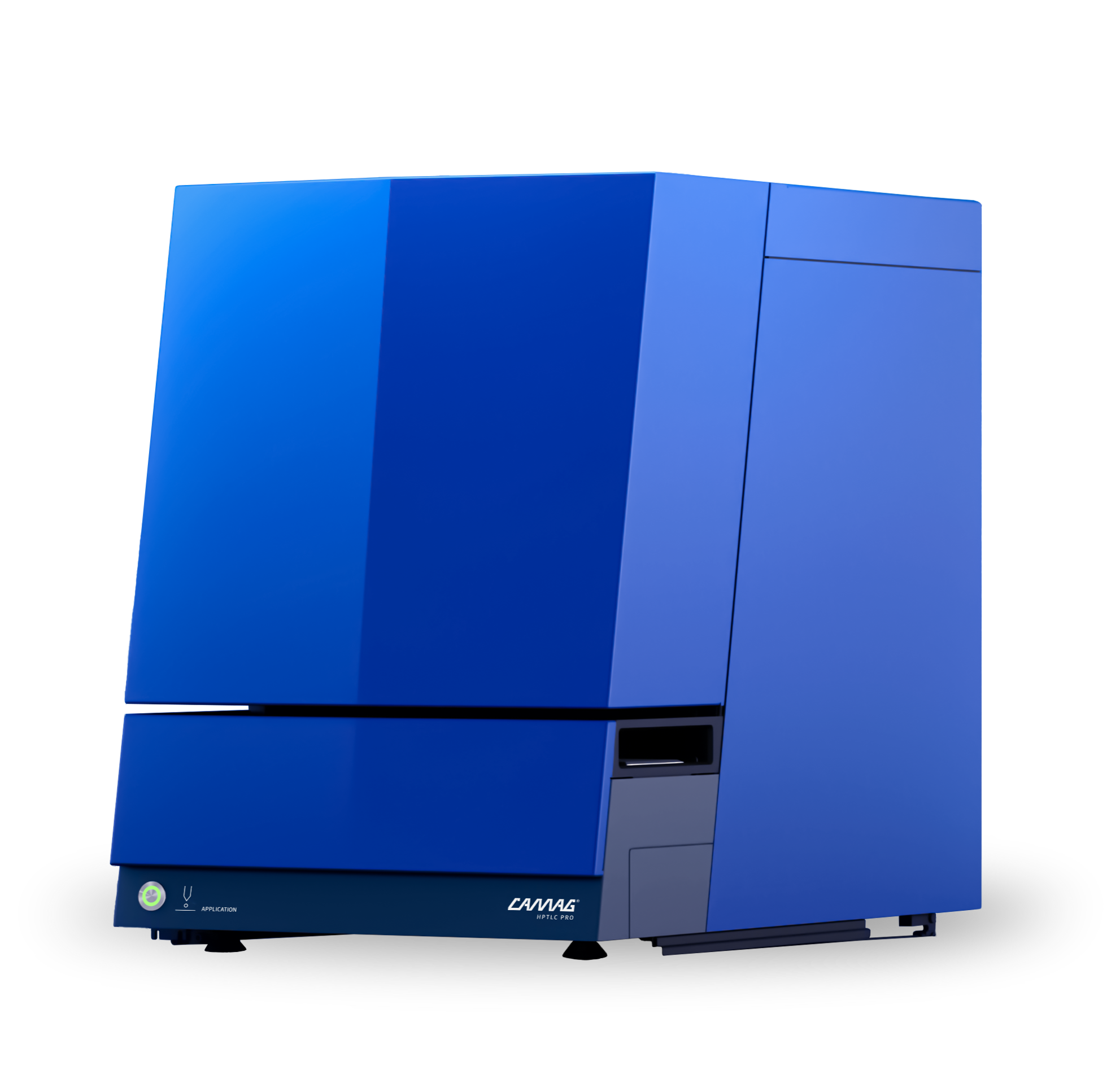

HPTLC PRO

Module Application

Module Application

In a nutshell

Precise and Consistent Sample Application for Reliable Results

Controlled by visionCATS HPTLC Software, the autonomous application of up to 75 samples is supported (on up to five HPTLC plates).

-

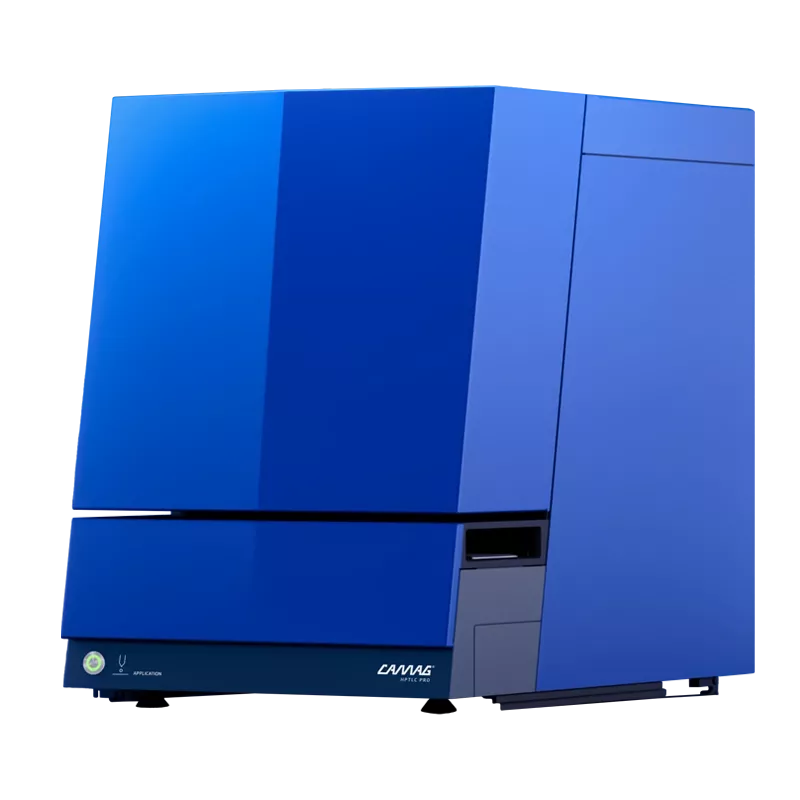

Part of the fully automated HPTLC PRO SYSTEM

-

Autonomous application of up to 75 samples

-

Spray-on application of samples as bands

-

HPTLC glass plates (20 x 10 cm)

-

Software-controlled by visionCATS

CAMAG® HPTLC PRO

System mode

CAMAG® HPTLC PRO

System mode

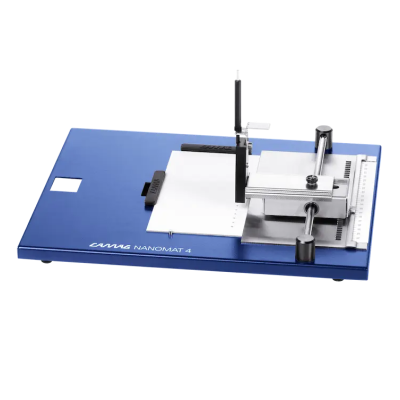

Stand-alone operation

When operated as stand-alone, the HPTLC plate is inserted on the left side and ejected on the right side after processing.

SMOOTH & PRECISE OPERATION

01

The HPTLC PRO Module APPLICATION can autonomously apply up to 75 samples across five different plates. For continuous operation, pair it with the Module PLATE STORAGE, which automatically supplies new plates.

02

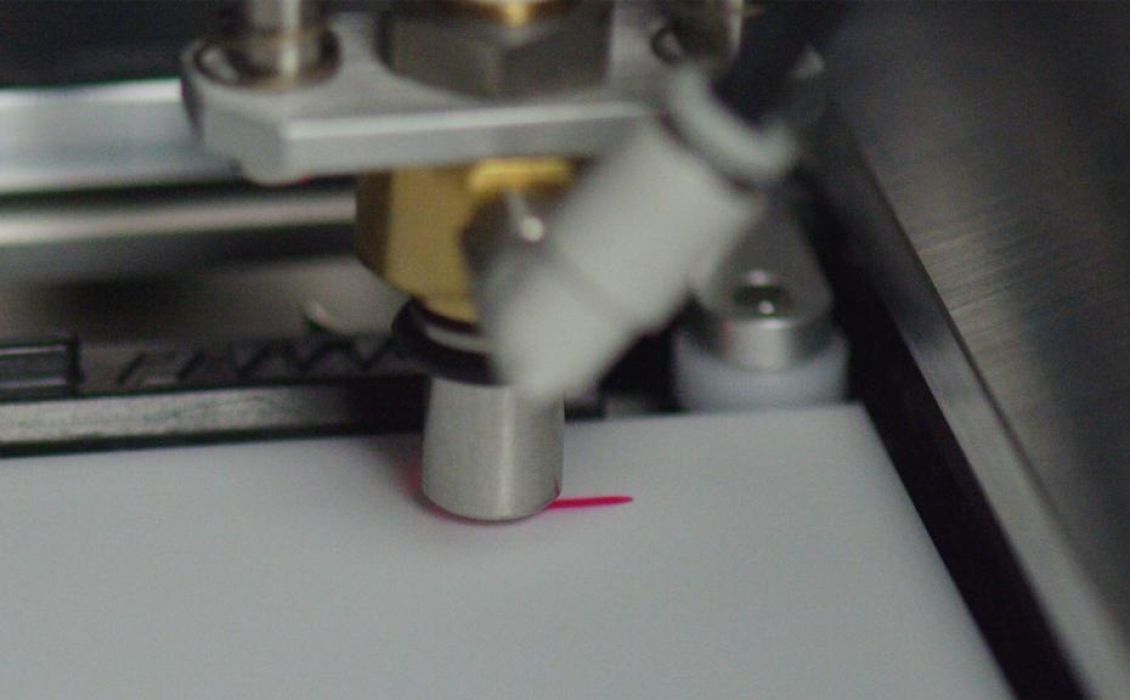

Laser-guided sample application ensures the optimal spraying distance. The needle distance and dosage speed adjust based on the solvent used, guaranteeing precise application of samples as narrow bands.

03

To prevent cross-contamination, the syringe creates an effective separation bubble between the rinsing solvent and the sample solution. The syringe is thoroughly cleaned after each sample application.

04

Following sample application, the integrated conveyor transfers the plate from the Module APPLICATION to the Module DEVELOPMENT for further processing.

KEY benefits

Highly precise application zones through optimized spraying procedure adapted for each sample solvent

Technical specifications

-

Classification of installation and useClass I, installation category II, protection class IPX0, Pollution degree 1

-

Nitrogen or clean air pressure5 – 8 bar (70 – 110 psi)

-

Operating temperature15 – 30 °C

-

Recommended working temperature20 – 25 °C

-

HumidityMaximum relative humidity 80 % for temperatures up to 30 °C (Humidity and temperature conditions must not cause condensation!)

-

Plate typesHPTLC glass plates 20 x 10 cm, layer thickness 200 µm

-

Operating voltage100 – 240 VAC; 50 / 60 Hz Fluctuations ±10 % of the nominal voltage Overvoltage category II

-

Power consumption40 W

-

Fuses2.0 AT, 250 VAC

-

Max. supply current from power outlet8 A

-

Dimensions (W x D x H):384 x 550 x 510 mm

-

Weight~ 33 kg

What you need to get started

Ordering Information

-

060.2000

CAMAG® HPTLC PRO Module APPLICATION

Can be operated either as stand-alone or as part of the fully automated CAMAG® HPTLC PRO SYSTEM. Allows the autonomous application of up to 75 samples as bands onto HPTLC glass plates (20 × 10 cm). Includes 10 μL Syringe (695.20001-1) and Spray-on needle (695.20000-1), 2 Carriers for HPTLC glass plates (20 × 10 cm), set of bottles for start-up, and Rack for 75 standard 2 mL vials (060.2100).

Interested in the product?

Reach out to your local distributor and enjoy faster, improved results at reduced costs.