CAMAG®

Automatic Developing Chamber 3

In a nutshell

the new standard for reproducible development

The CAMAG Automatic Development Chamber 3 (ADC 3) continues the proven reliability of its predecessor in High-Performance Thin-Layer Chromatography (HPTLC), offering consistent, fully automated plate development to support reproducibility and data integrity.

Designed for 20 x 10 cm HPTLC plates, the ADC 3 features an integrated Twin Trough Chamber that ensures stable analytical conditions and minimizes variability. It offers full flexibility in solvent selection and development parameters, supporting a wide range of applications.

All critical steps – saturation, activation, pre-conditioning, development, and drying – are fully automated to eliminate environmental influences and deliver reproducible results. The built-in humidity control enables chromatography at defined layer activity, essential for robust method development and for evaluating humidity effects.

Seamless integration with visionCATS software ensures compliance with cGMP/GLP and 21 CFR Part 11, making the ADC 3 a reliable choice for regulated laboratories that demand precision, traceability, and efficiency.

-

Fully automated chromatogram development

-

Integrated Twin Trough Chamber (20 x 10 cm)

-

Built-in humidity control for enhanced reproducibility

-

Software-controlled by visionCATS

-

Compliance with cGMP/GLP and 21 CFR Part 11

DESIGNED FOR THE LABORATORY

The ADC 3 simplifies lab work with efficiency, reliability, and flexibility. Whether you’re handling routine quality control or complex samples, it seamlessly adapts to your workflow. visionCATS HPTLC software allows you to define all parameters to meet your specific needs, offering complete control and full traceability.

Consistent Results Across Labs

The ADC 3 minimizes variability arising from both operators and laboratory environments, ensuring repeatable results every time.

Precision Through Automation

Fully automated plate handling and built-in system checks reduce user errors and improve reliability.

Increased Productivity

Automated plate development allows analysts to multitask during runs, improving overall workflow efficiency.

Regulatory Compliance

visionCATS integration enables secure parameter control, traceability, and data recording, supporting compliance with cGMP/GLP, and 21 CFR Part 11.

BUILT FOR THE USER

The ADC 3 is fully controlled via the visionCATS HPTLC software, enabling automated development with maximum reproducibility and compliance. Key parameters are precisely managed, including:

- Timing for chamber saturation, plate activation, pre-conditioning, and drying

- Solvent introduction during saturation, pre-conditioning, and development

- Monitoring of migration distance and development time

- Monitoring of temperature and relative humidity

Thanks to its intuitive interface, visionCATS guides users of all experience levels through setup and execution. Once all preparatory steps are complete, the system performs the development fully automatically under standardized conditions, allowing the user to focus on other tasks.

The entire process is continuously monitored and all data is recorded in accordance with cGMP/cGLP requirements. After development is complete, the plate is ready for the next process step of the HPTLC workflow.

HOW THE ADC 3 WORKS

Pre-drying

After sample application, the plate is subjected to a controlled pre-drying process. A built-in blower operates for a defined duration, eliminating any remaining solvent from the stationary phase, ensuring optimal conditions for reproducible results.

Chamber Saturation

Before development, the twin-trough chamber is saturated with solvent vapors to create a consistent internal atmosphere. This ensures uniform distribution of vapors across the plate. A saturation pad further enhances vapor dispersion, contributing to reliable chromatographic behavior.

Pre-conditioning

During pre-conditioning, the dry stationary phase is exposed to solvent vapors in a controlled environment. Solvent molecules present in the gas phase interact with the surface of the stationary phase, leading to modification of its properties.

Plate Activation

In most standardized methods, the plate is activated with air at a controlled relative humidity. Within a closed system, humidity is regulated using a saturated salt solution or molecular sieve.

Post-Development Drying

Once the development reaches the target migration distance, the plate is transferred to a drying unit. A controlled blower removes remaining mobile phase solvents, preparing the plate for the next analytical step.

Rinsing Procedure

When switching solvents, the system can be rinsed by adding solvent to the funnels. The glass tank can either be easily replaced with a clean one or cleaned and dried for reuse.

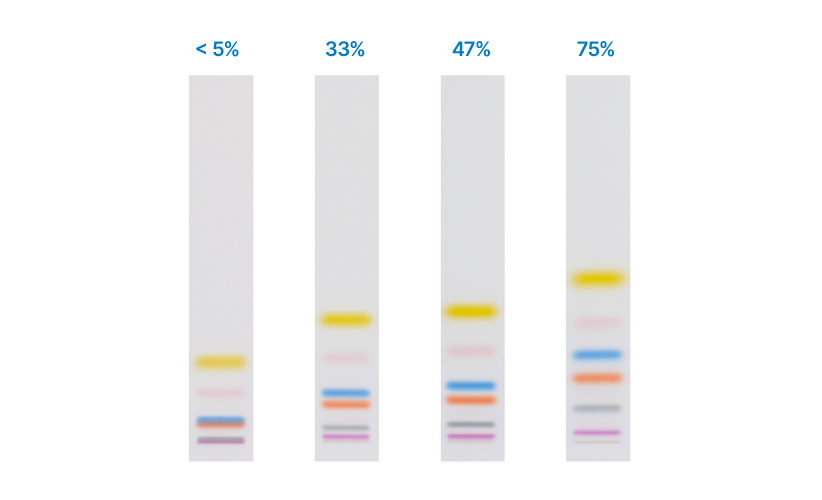

CONSISTENT RESULTS THROUGH CONTROLLED HUMIDITY

Chromatographic separation on HPTLC plates is affected by humidity, which can vary by season and location. The CAMAG® ADC 3 features a fully integrated humidity control, automatically regulating relative humidity around the plate. This enables both standardized and custom settings, ensuring reproducible results under changing environmental conditions.

Technical specifications

-

Classification of installation and useClass I, installation category II, protection class IP20, Pollution degree 1

-

Operating temperature15 – 30 °C

-

Recommended working temperature20 – 25 °C

-

HumidityMaximum relative humidity 80 % for temperatures up to 30 °C (Humidity and temperature conditions must not cause condensation!)

-

Maximal altitude2’000 m

-

Plate typesHPTLC glass plates 20 x 10 cm, layer thickness 200 µm

-

Operating voltage100 – 240 VAC; 50 / 60 Hz Fluctuations ±10 % of the nominal voltageOvervoltage category II

-

Power consumption60 W

-

Fuses2.0 AT, 250 VAC

-

Dimensions (W x D x H):315 x 320 x 495 mm

-

Weight~ 17kg

Ordering Information

-

022.8600

CAMAG® AUTOMATIC DEVELOPING CHAMBER 3 (ADC 3)

For fully automatic development of TLC/HPTLC plates of 20 x 10 cm, including CAMAG Twin Trough Chamber for ADC 3 (022.5262), for 20 x 10 cm plates, 100 – 240 V

-

028.0000

CAMAG® HPTLC Software visionCATS: Basic Version

including access and control of all instruments – 1 server, 1 client Instrument Diagnostics (xQ), analytical reports – access to method library. Needs to be purchased separately and is not included in any Ultimate Package.

-

022.5262

CAMAG® Twin Trough Chamber for ADC 3

For 20 x 10 cm plates

-

022.8376

Filter paper for chamber saturation ADC 3

Pack of 100

-

022.8373

Foils clamping device complete for ADC 2/ADC 3 (from S/N 130601)

Interested in the product?

Reach out to your local distributor and enjoy faster, improved results at reduced costs.