This case study demonstrates a reliable characterization of impurities in biodiesel (according to UNE EN 14214:2013) and additionally presents the concept for identity confirmation of monoacylglycerides by mass spectrometry, which allows for origin identification.

Introduction

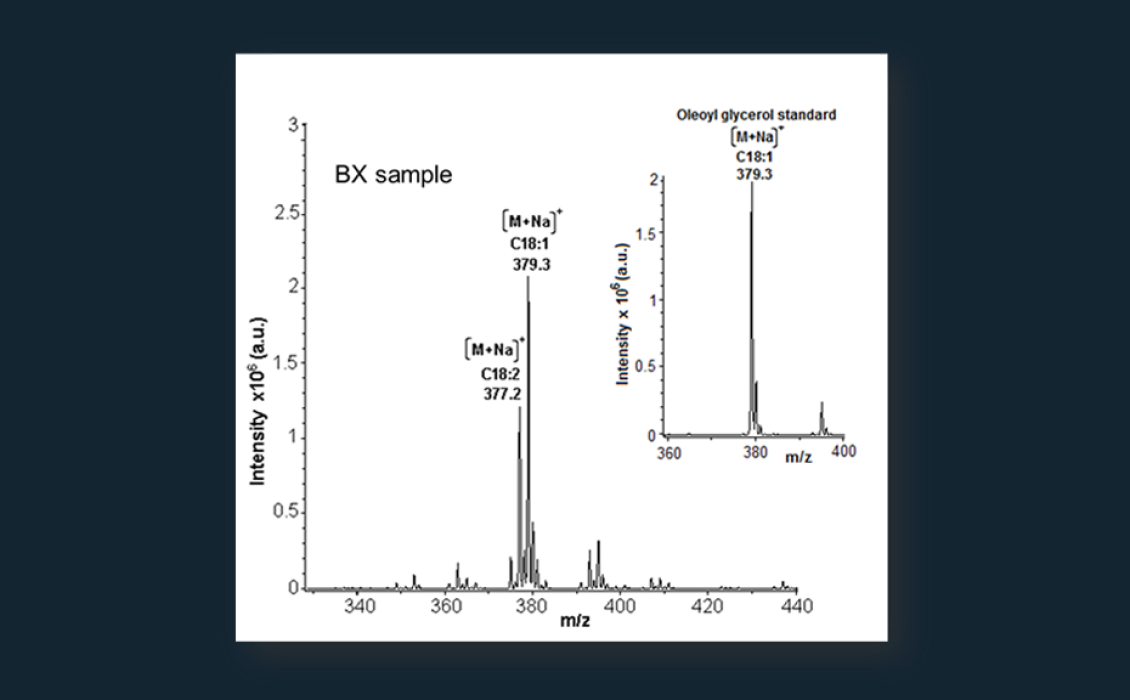

HPTLC is a powerful technique with high sample throughput capacity, short analysis time, and low running costs. This case study demonstrates a reliable characterization of impurities in biodiesel (according to UNE EN 14214:2013) and additionally presents the concept for identity confirmation of monoacylglycerides by mass spectrometry, which allows for origin identification (e.g. vegetable, animal, waste cooking oil).

Challenge

Often chromatographic techniques require time- and cost-intensive sample preparation steps. However, in many cases HPTLC allows to analyze samples after a minimal sample preparation (e.g. dissolving) in combination with the separation of several samples side by side on the same plate. Quantification of the separated compounds is possible by densitometry using the CAMAG TLC Scanner. In addition, the identity can be proven by eluting the spot of interest using the CAMAG TLC-MS Interface and coupling it to any commercially available mass spectrometer.

Description of the procedure and documentation

Sample and standard preparation are performed according to Cebolla et al. (CBS 114, p. 5-7). All parameters (conditions for sample application, chromatogram development, and evaluation) are logged into the winCATS software, which controls all major CAMAG instruments required for the HPTLC analysis. The samples and standards are applied band-wise onto the HPTLC plate using the ATS 4, which guarantees precise and reliable application. Then the HPTLC plate is developed using the AMD 2. For the analysis of monoacylglycerides the developed plate is dipped into primuline reagent. For quantification each track is scanned in fluorescence mode at 366/>400 nm with the TLC Scanner and evaluated with winCATS software. If further investigations of separated sample components are of interest, their eluted zones can be analyzed with other techniques like MS, NIR, and NMR (off-line hyphenation).

01

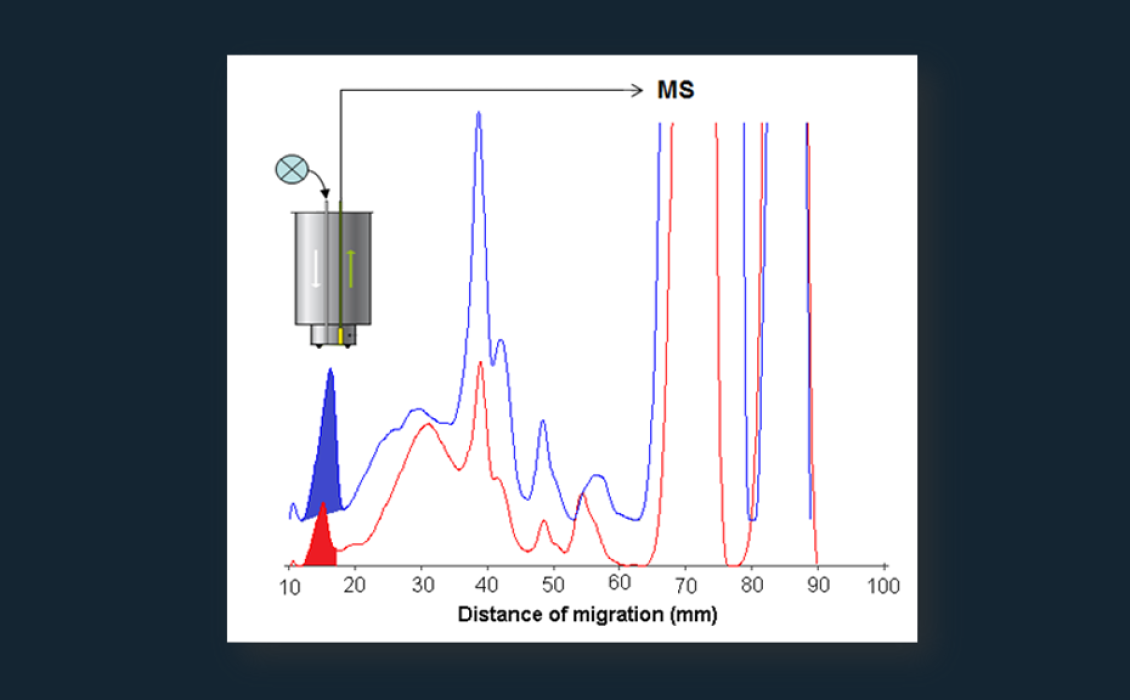

Densitogram comparison of B5 (red) and B20 (blue), both 5000 μg/band: monoacylglyceride bands at 16 mm were eluted via the TLC-MS Interface into the ESI-MS

02

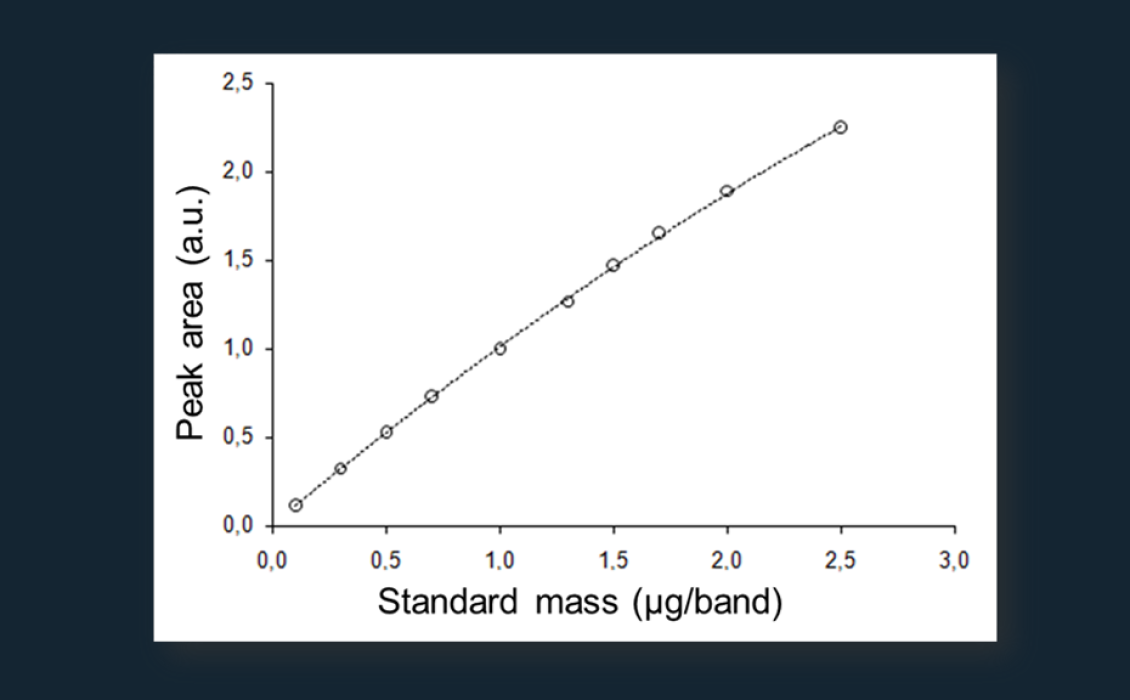

Polynomial calibration curve of the 1-oleoyl glycerol standard (y = -0.070 x2 + 1.077 x + 0.006; r2= 0.999)

03

Online monitoring of the purification process by LC-UV (254 nm, left) versus offline by HPTLC-UV (individual fractions at 254 nm, right)

Benefits of using modern HPTLC for industrial applications

- HPTLC can be used as high throughput and low-cost technique for a broad variety of analytical tasks in industrial applications settings.

- By using internal or external chemical reference standards compounds can be quantified precisely with the TLC Scanner.

- The entire sample is detectable on the plate and allows evaluation of all components even if some of them remain at the application zone or migrate in the solvent front.

- HPTLC can analyze samples with high matrix content due to the disposable stationary phase.

- Thanks to the non-destructive nature of the chromatographic method, analytes can be eluted after separation from the plates using the CAMAG TLC-MS Interface and analyzed by hyphenated techniques (e.g. MS, NIR, NMR).

This work was done at the CSIC, Instituto de Carbochímiqa, in Zaragoza, Spain. We are grateful to Prof. Dr. Vicente Cebolla and his team for the excellent collaboration!